In the field of parts crack and grinding burn detection, the multi-frequency and multi-filter technology developed by Bockner is a great breakthrough in the field of global eddy current technology. It has the following characteristics:

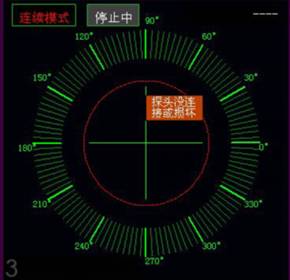

Probe abnormal alarm function, mechanical failure and operation error may cause the damage of the probe. If the damaged probe continues to use, it will cause serious missed detection. The multi-frequency and multi-filter eddy current flaw detector can self-check the probe in real time. If the probe is damaged, the operator will be prompted immediately in a striking way to avoid malfunction.

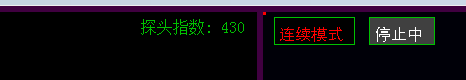

Probe exponential function. The detection performance depends largely on the quality of the probe and the rationality of the installation of the probe. We adopt a unique algorithm to synthesize the parameters of the probe, and create the concept of "probe index", which reflects the comprehensive performance of the probe, and guides the debuggers to the greatest extent, so that they can follow the rules in the adjustment of flaw detection and greatly reduce the adjustment time.

Independent of computer work, multi-frequency and multi-filter eddy current flaw detector adopts modern advanced electronic technology and fully digital design. At present, other flaw detectors rely on one or more computers for data processing, highly dependent on computers. The disadvantages of this method are: instrumentation stability is poor, the quality and service of equipment depends heavily on third parties, large volume, poor substitution. Our new generation of flaw detector adopts advanced DSP and FPGA technology. It has complete flaw detection functions such as data acquisition, data analysis, alarm analysis and so on. It can work completely without the computer. The computer used in the instrument is only used as a man-machine interface, so the requirement for the computer is greatly reduced. It is more convenient to change and maintain.