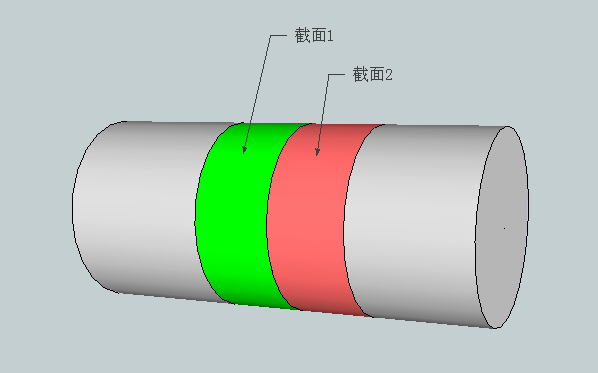

1. Probe configuration on the spindle section 1

A total of 3 probe adjustment frames are placed on section 1 at intervals of 120°. Each of the adjustment frames is equipped with a 2-channel combined ultrasonic line focusing longitudinal probe to detect longitudinal defects of the steel tube in a clockwise direction.

Detection of defects: Vertical and vertical defects in the steel pipe are detected in a clockwise direction.

Center frequency: 5.0MHz ± 10%

Coupling method: water immersion method

Quantity: 3 sets of probes, each consisting of 2 wafers. These 3 sets of probes are evenly distributed in the circumferential direction of the workpiece, spaced 120° apart, on the same section. A total of 6 channels of water immersion probes.

2. Probe configuration on the main shaft section 2

A total of 3 probe adjustment frames are placed on section 2, separated by 120°, and a 2-channel combined ultrasonic line focusing longitudinal probe is arranged on each adjustment frame to detect longitudinal defects of the steel pipe counterclockwise.

Detection of defects: counter-clockwise detection of longitudinal defects inside and outside the steel pipe.

3, the center frequency: 5.0MHz ± 10%

4, coupling method: water immersion method

5. Quantity: 3 sets of probes, each consisting of 2 wafers. These 2 sets of probes are evenly distributed in the circumferential direction of the workpiece, spaced 120° apart, on the same section. A total of 6 channels of water immersion probes.

Defect detection standard

Vertical and horizontal defects detection of ultrasonic steel pipe inside and outside: GB/T5777-2008 L2 (C5) standard